Your cart is empty

I stepped out of my truck into the inky blur of predawn light on a Thanksgiving morning, and it felt like the 15 degrees the thermometer had indicated. While the Hudson Valley had received a rain storm, the Catskill Mountains — specifically those locales above 2,000 feet in elevation — had been carpeted in snow, roughly two inches, perfect for tracking. I hadn’t gone a quarter-mile down the logging trail when I came across prints from a doe and her fawn coming down off the hill to my right. Within another 50 paces, the huge track of what could only be a buck joined the trail, drifting slightly left and right like a heat-seeking missile.

She was obviously a hot doe, and I was no longer concerned about the 15-mph wind and blowing snow.

With the tracks just minutes old, I followed on cautiously, a steely focus narrowing. This scenario had my undivided attention. Stopping before a small rise in the trail, the slightest glimpse of a heavy set of antlers caught my eye, disappearing behind a downed beech tree. The rifle came to shoulder effortlessly, and the instant he cleared the obstruction, my .308 Winchester sent a 165-grain Nosler Partition into his vitals. I soon stood over a beautiful eight-point buck surrounded by the idyllic Catskill Mountains, cradling a rifle handed down to me by my father. He had stopped hunting a couple years earlier, but I’ve carried on our Thanksgiving Day hunting tradition.

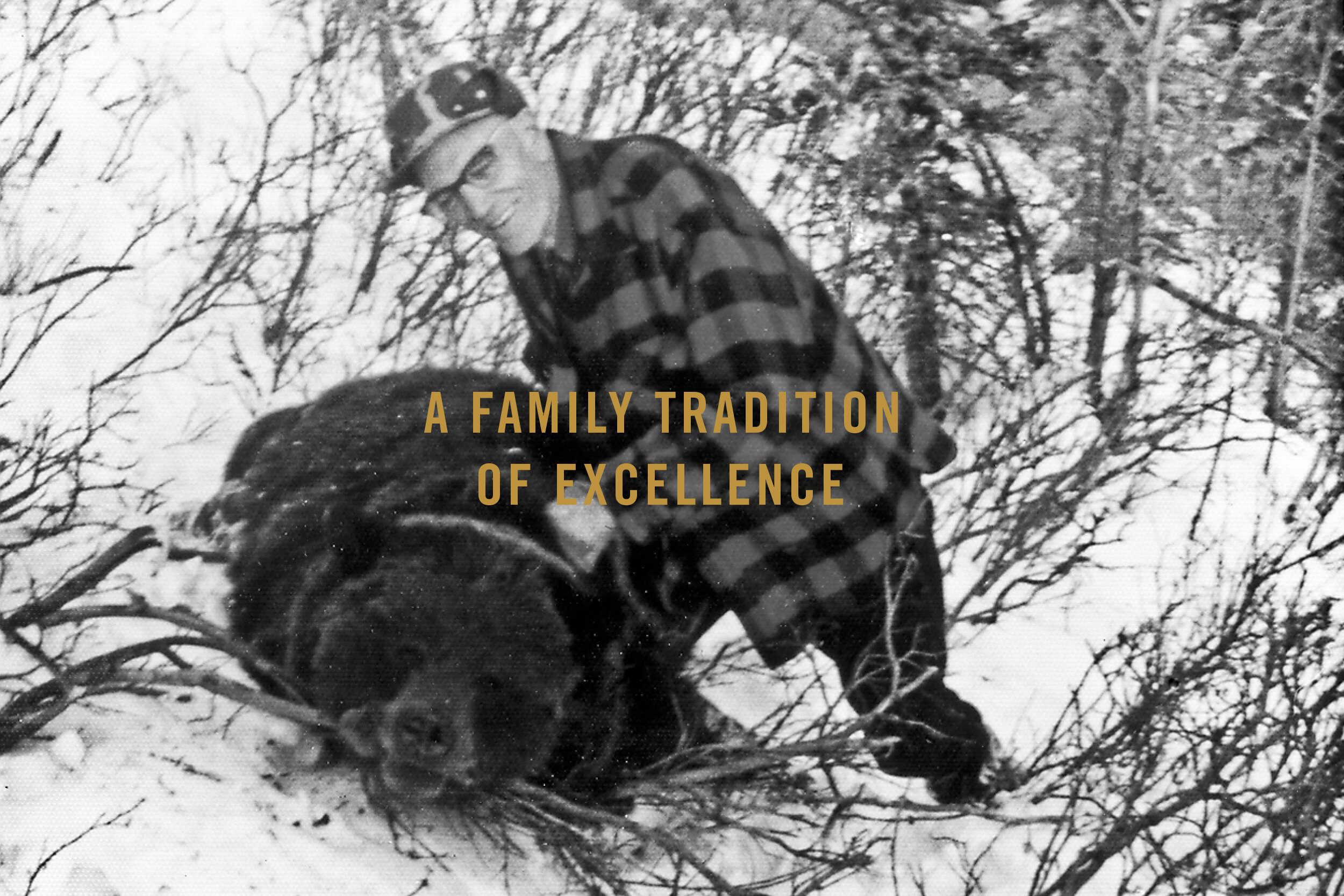

“There are big bears up there; load some Partitions for that hunt,” he’d always say. Dad was, as usual, correct.

My dad and I are business partners, and have hunted all over the world together, so I can appreciate the trials, tribulations and rewards of a family business. In the hunting and shooting industry, many of the best companies either started out being or still are family run, and I can think of no better example of this than Nosler. The Partition, a flagship of the Nosler fleet, was the first bullet developed by avid outdoorsman John A. Nosler, the company’s founder.

The Nosler story began in 1946, as John settled the crosshairs of his .300 Holland & Holland on the shoulder of a mud-caked bull moose in British Columbia. Much to his consternation, but to the benefit of the hunting world, the speedy bullet failed to penetrate properly, leading to a protracted follow- up. John wasn’t going to tolerate this, and spent the next several months brooding, determined to build a better mousetrap.

The bullet that failed Mr. Nosler was the standard bullet du jour, and in fact the non-premium standard to this day: a cup-and-core design. It’s simple and brilliant, using a jacket of copper (the cup) around a lead core. Upon impact, the copper jacket peels back, and the lead core deforms to create the classic mushroom. Under extreme stress, the jacket and core can separate, and can lead to penetration failures. This is exactly what happened to John Nosler on that fateful day that changed history, initiating his drive to build a bullet that would take any animal, of any size, at any angle. His goal — as is the goal of any ethical hunter — was to make a quick, clean kill, and to minimize the suffering of any game animal. A bullet that didn’t do its job fell short of the ethics he had been raised to consider.

A napkin sketch seeded his grand idea, which would be the catalyst for all manufacturers to scrutinize the terminal effectiveness of bullet construction. He would utilize a partition of copper across the middle of the bullet, preventing jacket and core from separating. In this way, the rear core would always remain intact, giving the bullet the ability to penetrate deeply into the vitals for a quick kill. He took his new design back to Canada the following autumn, and both he and Clarence Purdy took moose cleanly with one shot each, Clarence using his .30-’06 Springfield to take the first wild game with John’s new bullet. The bullet was a success, and the Nosler Partition Bullet Company was born in 1948.

GEN ONE

John Amos Nosler was born in Southern California, in April 1913, the fifth and last child of Byrd and Perna Nosler. His father had been born

on the Oregon Trail, and the family endeavored in a series of farming and ranching operations, from Colorado to California, as well as other ventures. Young John showed an aptitude for all things mechanical, fostered by his time spent alongside hot-rodded automobiles in an auto repair shop. He always had a penchant for the outdoors and hunting, with necessity playing some part in his hunting prowess.

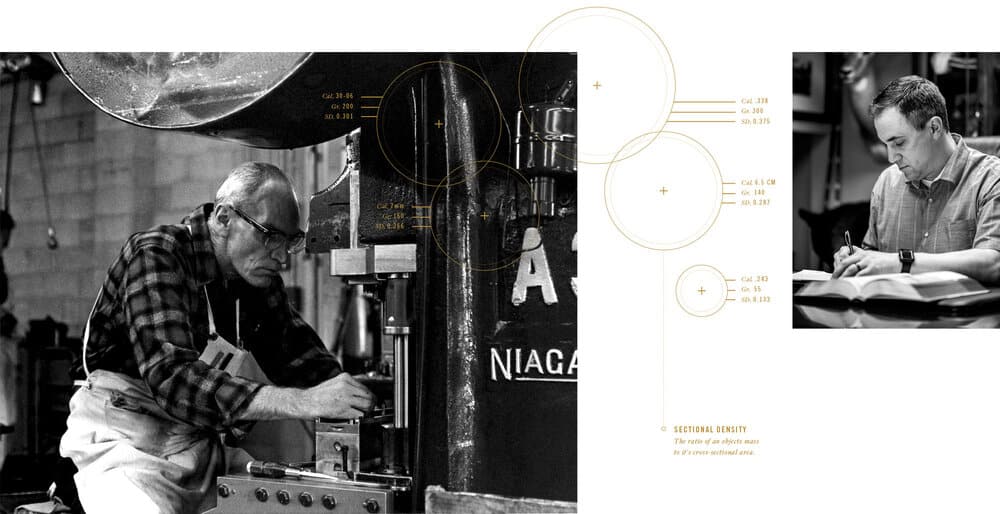

His experiences with the .300 Savage, .30-40 Krag and .348 Winchester had vividly illustrated the issues involved with overstressing a cup-and-core bullet, and how longer bullets with a higher Sectional Density gave better terminal performance than lighter slugs. These concerns and observations came from a man deeply invested in the morality of ethical hunting and the responsibility laid upon the hunter when harvesting a wild animal. The Nosler Partition design was revolutionary in 1948, and remains a hunting staple to this day. It has performed consistently, giving the desired expansion and deep penetration equated with quick, humane kills; the greater the upset bullet’s diameter, the larger the wound channel, and the greater the destruction to vital tissue. The initial bullets were made from copper rods cut to length, drilled at either end, with molten lead poured into the cavity. This was a time- consuming process, which would eventually be adapted as production scaled up. As such, the early days were a small-scale, family-and-friends affair, and before long, the little shop in Ashland, Oregon was up and rolling.

After initially producing his Partition bullets on lathes (the first of which he built himself), he developed the revolutionary impact extrusion method, making his bullets more consistent and therefore more accurate. Production was slow initially, but as John made the transition to his bullet company full-time, he acquired the machines necessary to ramp up output. In an effort to raise the profile of his creation, John connected with some of the preeminent writers of the day, including Herb Klein (who took the Partition to Africa), Warren Page, Elmer Keith and Jack O’Connor, and before long, the Nosler Partition was enjoying unanimous praise the world over. For hunters, the Partition became the baseline by which all others would be judged. With popularity increasing, John soon expanded, moving the Nosler plant to Bend, Oregon. His son Bob, born in April 1946, would follow his father’s footsteps and become an integral part of the company.

GEN TWO

From the inception of the company, John A. Nosler had taken on a partner in his business, Ray Wade; a pairing which without question helped facilitate the early success. But, Wade eventually wanted to sell his shares of Nosler, and the end of a long story is that the optics firm of Leupold & Stevens ended up owning Nosler as a subsidiary. During this time, John developed his second bullet, the Zipedo, which evolved into the Nosler Solid Base in the 1970s. The Leupold & Stevens years would hold some famous names — guys who I fondly recall from my youth. Chub Eastman, Gail Root, Bill Lewis; they would play an integral part in creating the Nosler we all know today, lending expertise in many different departments. By this time, the hunting and shooting world was beginning to embrace the premium bullet market, with manufacturers of loaded ammunition collaborating with premium bullet makers. Hunters now had more choice when it came to choosing their ammunition, and most importantly, the design of projectiles for their hunt. For the first time, real consideration was given to bullet construction, and the importance of understanding what was appropriate across varying species and circumstances.

The innovation at Nosler didn’t stop there. Their revolutionary Ballistic Tip — an idea influenced by a Norma projectile with a round polymer ball at the nose — was also a huge success. This design saw an impact extruded bullet with a tapering jacket, and a sharp polymer tip at the nose to both initiate expansion and maintain the ballistic coefficient. It is fantastically efficient for rapid energy transfer, making it a perfect choice for deer, antelope and similar-sized animals, and today has been adopted in varying fashion by a number of manufacturers. The larger species are still best handled by John’s Partition, but the Ballistic Tip — if of proper weight — is hard to surpass. Bob’s business acumen complemented his father’s well. He was responsible for ending the financial relationship with Leupold & Stevens (though they remain on excellent terms), and in 1988, brought the company back under family ownership, setting the stage for the introduction of his son John and daughter Jill. This era would also see strong partnerships forged with both Federal and Winchester — both loading Nosler bullets in their line of factory ammunition — bringing the Nosler name to the masses, and allowing those who didn’t handload their ammunition to enjoy the benefits of the Nosler line.

GEN THREE

John R. Nosler, the third and current generation of Nosler, fully understands the pressure of being in charge of such a prestigious company, and yet remains a down-to-earth guy. While I’ve been privileged enough to have met both Bob and young John Nosler at the trade shows, I recently had a chance to chat on the phone with John in a much more relaxed atmosphere. “I won’t say I was groomed for this position — I had the choice to pursue any avenue I wanted to — but I will say I had two of the best mentors anyone could’ve asked for: my father and my grandfather,” John told me. “I couldn’t fill my grandfather’s shoes, and I’m not the man my father is, but I’m proud to be me.”

“I won’t say I was groomed for this position — I had the choice to pursue any avenue I wanted to — but I will say I had two of the best mentors anyone could’ve asked for: my father and my grandfather,” John told me. “I couldn’t fill my grandfather’s shoes, and I’m not the man my father is, but I’m proud to be me.”

John has been on board for the most radical expansion of the Nosler brand, including the introduction of the Nosler AccuBond, AccuBond Long Range, RDF and E-Tip bullets, as well as the line of Nosler rifles, loaded ammunition and cartridges. As a matter of fact, he just completed the Grand Slam of North American wild sheep, and did it using the four new Nosler big game cartridges. An impressive feat for any hunter, anywhere, it must have carried all the more significance owing to the head stamp of the cartridges used.

My dad, Bob, made a big push to diversify the Nosler name, without watering it down or cheapening it,” John explained. In the tradition of John A. Nosler, the subsequent generations have the knack for recognizing the needs of the hunting and shooting community. The Nosler AccuBond is an improvement on the Ballistic Tip concept, in that the polymer tip helps to keep the bullet’s meplat, or nose, consistent and resistant to deformation in the magazine. Further still, the markedly thicker jacket is chemically bonded to the jacket, slowing down the expansion, which allows the bullet to penetrate deep into the vitals before losing momentum. The bonding, the polymer tip, the boat tail and the accuracy all help to make the AccuBond a bullet capable of handling the high-impact velocities of a magnum cartridge, yet still expand at long ranges when the bullet’s velocity drops off. To some, this may feel a little technical, but selecting the right bullet is crucial, and without question, the ethical hunter has a responsibility to understand, to a certain degree, how to choose the appropriate bullet design for the quarry being pursued. The AccuBond is a wonderful bullet, and along with its excellent terminal performance, it produces tiny target groupings from a number of my rifles.

I asked John a little more about the diversification of the company, and

how this complements the core of their business. “We are also very proud of our component brass cases, and the Nosler series of loaded ammunition. We took a big leap when we offered our line of ammunition, as we have been known as a component bullet company since the late ‘40s. We have a great partnership with both Winchester and Federal, who load our bullets, and we didn’t want to compromise those relationships in any way.”

Now, I can attest to the fact that the Nosler component brass offers a quality hard to match; it comes out of the box ready to go, and doesn’t require any of the prep-work associated with some other brands. When I loaded my .280 Ackley Improved ammunition for a safari to Namibia, I reached for Nosler cases; the accuracy and consistency was phenomenal. I’ve also come to appreciate the quality of Nosler’s factory ammunition, from the varmint loads to the deer, bear and elk offerings, right on up to the safari ammunition for large bore rifles. Their Partition is a great choice for big game animals, and the Nosler Solid — a lead-free, non- expanding bullet — is a perfect choice for backup shots on dangerous game.

Nosler has also embraced the global movement toward lead-free ammunition, both for big game and varmint hunting. Nosler’s ExpansionTip is a lead-free copper-alloy bullet, with an O.D. green polymer tip over the patented E2 cavity. The tip is used to initiate expansion upon impact, driving the sidewalls outward, expanding the bullet for optimal performance. Comparing a homogenous copper alloy bullet to one of the same weight with a lead core, you’ll find the former much longer than the latter. Copper is lighter than lead, and so to achieve equivalent weights, a longer projectile is needed. The E-Tip will tend to run at middle-of-the-road weights for caliber, and all the reports show that this bullet has fantastic penetrative qualities and performance. Staying with the ‘green’ mentality, Nosler also offers their Ballistic Tip Varmint in a lead-free configuration, giving the same frangible jacket and explosive expansion as its lead core counterparts.

We shooters and hunters have a wide field of cartridges to choose from, so

it was a risky proposition when Nosler announced their own line of proprietary cartridges. “We were slightly concerned about how they’d be received, but by the time we released the .28 Nosler— second in the series — we knew we would be okay,” John explained. The Nosler big game cartridges are based on the rimless .404 Jeffery cartridge, with the walls blown out to maximize capacity, and shortened to fit in a standard .30-’06-length receiver. There are currently five, spanning from the 6.5mm 26 Nosler to the largest, the .338-caliber 33 Nosler. In addition, an AR-15 designed 22 Nosler completes the lineup.

“When I asked John what he’d say to the new shooter or hunter who asked why they should buy Nosler products, he paused for a brief second, and rather than recite some preconceived mission statement, he gave it to me straight. “We want our customers happy, and if they’re not, we’ll do what is necessary to make it right. Nosler isn’t the cheapest, but it represents the best value out there. There is no ‘good enough’ at Nosler; we strive for the absolute best.”

In finishing up my conversation with John, he emphasized the importance of the people who make Nosler what it is today. “The Nosler of 2020 is like one large family unit. I’m blessed to work with my father, mother, sister and two brothers-in-law, but our team — those people who we rely on daily — are like family to us; they believe in the Nosler brand, and take their jobs very seriously. We have done our best to assemble the dream team. Guys like Jeff Bailey, Zach Waterman, Pat Mundy, Mason Payer, Mike Lake and Jeff Sipe, and there are others. We all share the same vision,” John proudly stated. When I asked John what he’d say to the new shooter or hunter who asked why they should buy Nosler products, he paused for a brief second, and rather than recite some preconceived mission statement, he gave it to me straight. “We want our customers happy, and if they’re not, we’ll do what is necessary to make it right. Nosler isn’t the cheapest, but it represents the best value out there. There is no ‘good enough’ at Nosler; we strive for the absolute best.”

Lastly, I asked what I thought to be an obvious question: would any of his children be following in the family footsteps? “Well, my son Robert, named after my dad, has the same engineering mindset my grandfather had, and at 10 wants to get into reloading. If he wants it, he’d certainly be a natural fit.” Personally, I’d like nothing more than to see a fourth generation of Nosler continuing the tradition, and I know the Nosler family feels the same way.

For generations, the Nosler name has been synonymous with hunting. My dad introduced me to both the Partition and Ballistic Tip, and they became an integral part of our personal hunting traditions as we reloaded our ammunition. Today, I’ve happily brought the E-Tip and AccuBond into my lineup. As a hunter and shooter, I’m grateful for a family as dedicated to their craft as the Noslers are, and

I look forward to the continuation of their tradition for innovation. John Amos Nosler’s hard work, sweat and focus has been handed to his son, and in turn to his grandson, but each has a healthy respect for that which has come before, and each has made an indelible mark on the company’s history as well as the shooting industry. From a brilliant sketch on a paper napkin, to one of the most innovative ammunition companies in existence, the Nosler product line will continue to help hunters around the globe make memories and put food on the table.

John Amos Nosler left this life on October 10, 2010 at 97 years old, but he still walks among us. His gift to the hunting tradition lives on in his children, grandchildren and great- grandchildren, and every time a hunter or shooter sends a Nosler bullet down their barrel.

Related Stories

Latest Stories